The Modula is a hybrid locomotive concept with different traction modules on a standardised centre-cab locomotive platform. These systems have the same interfaces so that, for example, the two diesel engine unit can be replaced by a two battery unit.

Variants:

- BDD (small battery + two diesel engines)

- EDD (electric traction + two diesel engines)

- EBB (electric traction + two larger batteries)

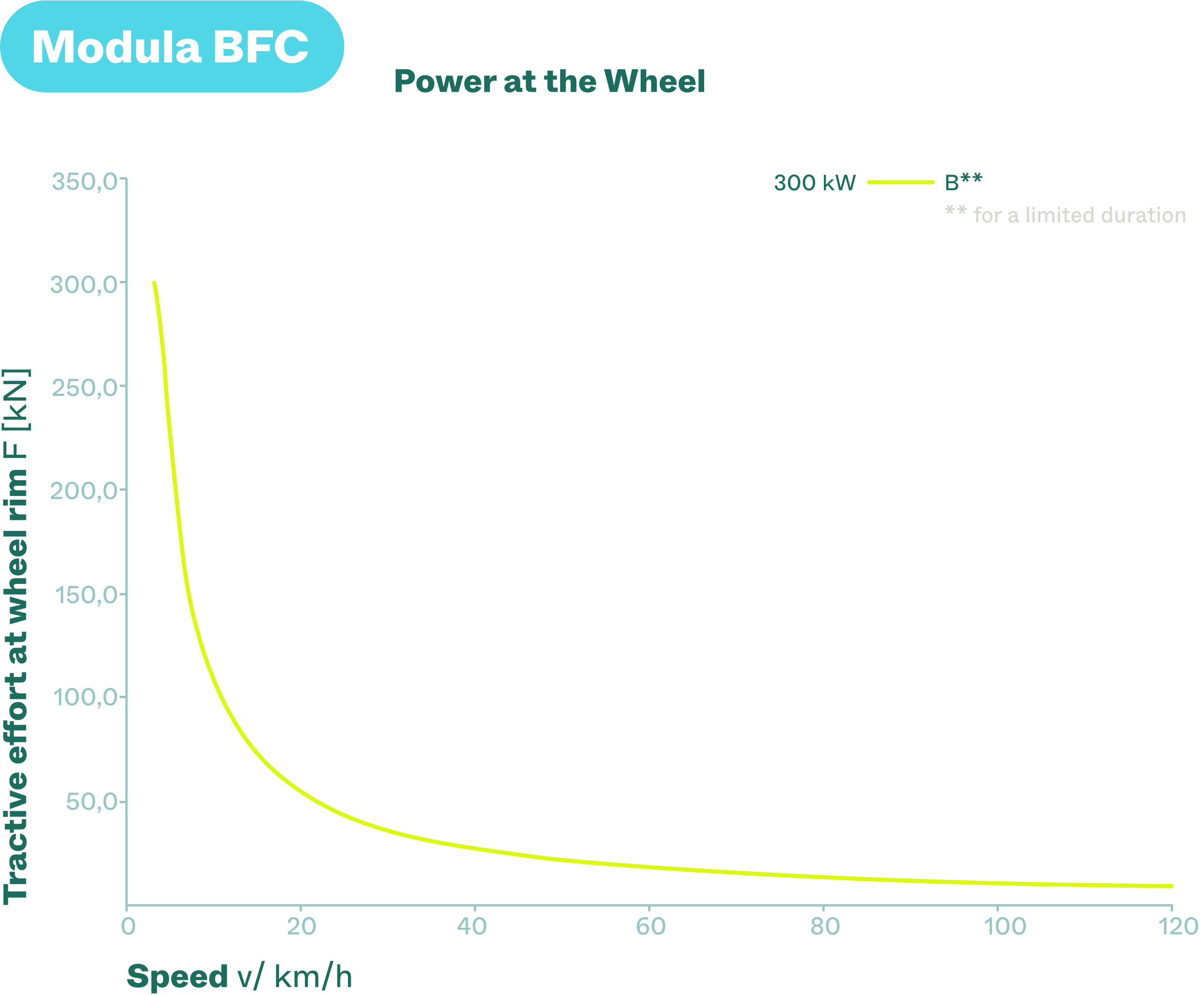

- BFC In addition a BFC (Fuel Cell traction system) is in development as a further traction variant

This modularity allows the operator to adapt the locomotive quickly and easily to changing requirements. It offers a range of standardised functions and systems that can be assembled into customised versions to suit the customer’s specific requirements. With its high proportion of identical parts, the platform concept provides synergy effects and simplifies the management of replacement parts.

The Modula combines the characteristics of a main-line locomotive with those of a classical shunting locomotive, and the focus here is on flexible power sources. The customer’s application profile can be used to combine two power sources to make a single variant.

The control system in the Modula is designed with the future in mind; it can be upgraded with new functionality even years after delivery. It can also be equipped with a digital automatic coupling, a camera to identify obstacles or Augmented Reality applications for servicing. And if the locomotive’s intended use changes in the future, modifications can also be carried out accordingly.